Tubes Filling Machine mo plasticlaminate ma alumini paipa (e oo atu i le 320 ppm)

FAAMATALAGA O MEA FAI

Fa'amatalaga Puupuu o le masini fa'amaufa'ailoga pa'u palasitika

1. O lemasini fa'amaufa'ailoga paipa palasitikafa'aogaina le Siemens 10-inisi mata pa'i ma le Japanese Keyence PLC-KV8000 polokalama fa'atonutonu.

2. paipa o le faatumu pulea faiga servo faagaoioia ma le faagaoioiga pulea manatu

3. Puleaina galuega: A uma ona aveese le paipa poʻo le gaosiga, o loʻo i ai pea se paipa e tumau i le filifili paipa - tapuni.

4. Galuega saogalemu (fa'alavelave fa'afuase'i ma ki puipui) e feso'ota'i faitoto'a uma pe a fa'agasolo le paipa o fa'atumu.

5. masini faʻatumu paipa faʻapipiʻio lo'o fa'amatala uma masini fa'ailo e mafai ona fetu'una'i e ala i le vaega fa'atonutonu

6. O le servo eletise o le paipa o le faʻatumu e mafai ona fetuunai le saoasaoa taʻitoʻatasi, ma e mafai ona fetuunai le saoasaoa o le gaosiga o le masini atoa.

7. O le masini inching e galue i le saoasaoa maualalo

8. Vaega autu e fetuutuunai faatulagaga uma gaosiga

9. O loʻo faʻaalia e le vaega faʻagaioiga le aofaʻi o le gaosiga ma le tulaga o le laina gaosiga

10. E tusa ai ma manaʻoga o tagata faʻatau, seti seti se tele o fua faʻatatau mo paipa faʻatumu

11. O lemasini faʻatumu paipa faʻapipiʻie mafai ona seti le vaega e pulea ai galuega tauave

12. O le masini faʻapipiʻi faʻapipiʻi otometi o loʻo i ai se vaega faʻaogaina e puipuia e 3 tulaga faʻaogaina eseese.

13. Kapoti eletise tutoʻatasi uʻamea uʻamea ma ea malulu, tulaga puipuia e oʻo atu i le IP65 poʻo luga.O fata uaea i le va o kapoti eletise ma masini e faʻaoga ai fata uaea tapuni, ma ua ulufale mai le pito i luga o le masini i se tulaga maualuga.

I le lumanaʻi, e mafai e le faiga faʻatonutonu ona faʻaoga Siemens profitnet e faʻafeiloaʻi faʻamatalaga i le MES ma faʻafesoʻotaʻi ma le MES system.

Tubes Filling Machine mo plasticlaminate ma alumini paipa

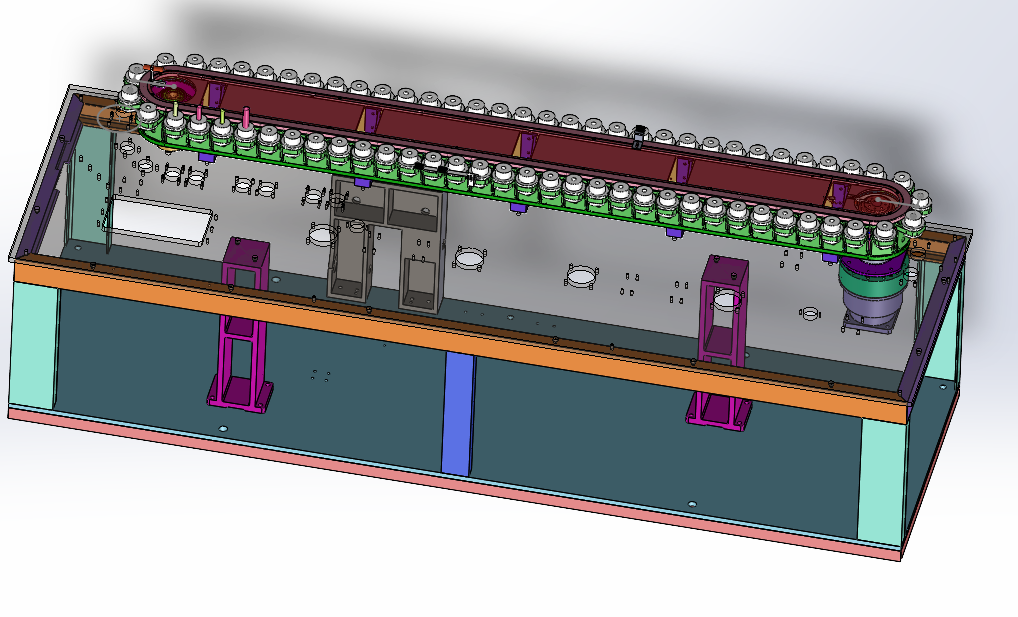

LFC4002Masini Faatumu Tubesose fa'atūlaga fa'atumu ma fa'amaufa'ailoga atoa-servo plastic tube fa'amaufa'ailoga masini tuto'atasi atina'e, mamanuina ma gaosia e la matou kamupani.E fetaui lelei mo le faʻatumuina o faʻamatalaga eseese o faʻamaʻi poʻo le le faʻamaʻaina alumini faʻapipiʻi faʻapipiʻi, paʻu palasitika ma alumini paipa.O le saoasaoa o le mamanu o le 360 tubes / minute, ma o le maualuga maualuga o le gaosiga masani o le faʻatumu o le faʻatumu o le 250-340 tubes / minute.O le faʻatumu saʻo o le ≤±0.5%.O le paipa alumini e faʻamaufaʻailogaina e ala i le gaugau faʻamaufaʻailoga, o le alumini-palasitika paipa faʻapipiʻi e faʻamaufaʻailogaina e le vevela vevela poʻo le faʻavevela maualuga, ma o le paipa palasitika e faʻamaufaʻailogaina e le faʻamaufaʻailogaina o le ea vevela vevela.

Tubes Filling Machine Fa'aauiga fa'asalalau:

Le masini faʻatumu otometi tubefa'aaogaina se u'amea u'amea ta'iala ta'iala, o se fa'agaoioiga e fa'amalo tolu-vai fa'au'u ipu fa'alava, ma se seti o le 4kW servo fa'ave'esea fa'alava fa'au'u ipu fa'avili masini filifili.O le masini faʻamaufaʻailoga paʻu palasitika e fuafua ai le maualuga o le saoasaoa ma le mautu o mea faʻapipiʻi.

Tubes Filling Machine paipa ipu filifili feaveai masini e aofia ai tolu grooved pito i luga, pito i lalo ma itu uʻamea ala taʻiala taiala.E tolu pa'u ta'avale o lo'o fa'apipi'iina i luga o le nofoa ipu fa'aau, ma fa'asolo fa'asolo i totonu o tootoo ma tuli le fa'agaau.O le filifili ipu paipa e leai se ofi.O lo'o i ai fo'i ni fa'avili nila e lua pito i luga ma lalo o lo'o fa'apipi'i i pine mo le feliuliua'i.

masini fa'amaufa'ailoga pa'u palasitika O le filifili fa'alava fa'agaau fa'agaau fa'amau fa'amau ma fa'apipi'i nofoa fa'apa'u (tulaga fa'amaufa'ailoga e tolu, alavai ta'iala u'amea) i le tasi ma le isi e ala i se fusi fe'avea'i nifo.O le fusi o le conveyor toothed e tamo'e sa'o lava e tusa ai ma le felauaiga ala o le uili avetaavale.O lo'o fa'apipi'i se ipu fa'apa'au i mama nofoa fa'agaau ta'itasi.O le ipu paipa e faia i mea POM ma faʻafeiloaʻi faʻamatalaga faʻapipiʻi ma manaʻoga mamanu.

Tubes Filling Machine conveyor filifili overload puipuiga e faia e se amataga toe faafoi saʻo synchronous torque limiter faʻapipiʻiina i luga o le uili faʻasalalau, lea e umi se olaga tautua.Afai e pipii le filifili paipa, ua motusia le pipii, ua faʻaoso le ki faʻalatalata, ma tuʻu loa le masini.

Tubes Filling Machine Fa'ainitaneti faiga fa'amama

1. Le masini fa'amaufa'ailoga paipa palasitikafaʻatumu faiga ma hopper e mafai ona otometi ona faʻamamāina e le CIP station i totonu o se matasele tapuni i le taimi e tasi.

2. Aʻo leʻi amataina le CIP, o loʻo faʻapipiʻiina le pusi faʻatumu i se ipu faʻapitoa CIP dummy, ma o le vai faʻamamaina o le a faʻateʻa mai le masini faʻatumu e ala i le paipa e fesoʻotaʻi ma le CIP dummy cup.

3. O le fale faigaluega CIP (e tu'uina atu e le tagata fa'atau) e tu'uina atu ai le fa'amama i le faitoto'a o le pu.O loʻo faʻapipiʻi se polo faʻafefe i totonu o le paʻu, ma faʻapipiʻi e le polo faʻamama le mea faʻamamā i luga o le pito i totonu o le paʻu.O le faʻapipiʻiina o masini faʻamaufaʻailoga palasitika ua mamanuina e tusa ai ma mataupu faʻalesoifua maloloina, ma o le CIP faʻamamaina vai e mafai ona oʻo atu i luga uma, paipa ma meafaifaʻaili e faʻafesoʻotaʻi ma le oloa i le taimi o le gaosiga.O vaega fe'avea'i e fa'afeso'ota'i ma le oloa i le taimi o le gaosiga, e pei o pamu piston, agitators, ma isi, o le a fa'asolo fo'i i le taimi o le fa'amamaina o le CIP ina ia fa'amautinoa e mafai ona fa'amama atoatoa vaega uma.

4. O le paipa faʻafesoʻotaʻi mo le vai faʻamamaina e toe foʻi atu i le CIP system a le tagata faʻatau (e le o aofia ai le pamu faʻafoʻi i le lautele o le sapalai)

5. Fa'atūina le fa'amama ma fa'amama fa'ama'i e tusa ai ma mana'oga o tagata fa'atau, ma fa'amama uma ma fa'amama fa'amasani ua fa'atulaga i le CIP station

6. Parameters e pei o le vevela, mamafa, tafega ma le taimi o le taamilosaga CIP e mafai ona faʻatulagaina e le CIP station e tusa ai ma manaoga o tagata faatau.

7. E mafai foʻi ona vave faʻamavaeina le faʻapipiʻi faʻatumu o le masini faʻamaufaʻailoga paʻu palasitika mai le pamu mo le faʻamama tuusao.

8.CIP felauaiga manaʻomia 2T / H poʻo luga

Tubes Filling Machine fa'aaogaina robots e fafaga ai fa'agaau (15x2 paipa e ave i laina fa'alua i taimi ta'itasi, 9-12 taimi / minute):

E tusa ai ma le polokalame polokalame, o le robot e ave i fafo laina e lua o faagaau mai le pusa faʻamautu i taimi taʻitasi, faʻafeiloaʻi i le pito i luga o le ipu paipa, ona faʻapipiʻi saʻo i totonu o le ipu paipa.O lo'o fa'aogaina e le robot se auala lagolago fa'aapa'au, ma fa'aoga uamea e fa'amalosi ai tamatamai lima.Gauaia, e mafai ona fa'a'ese'ese mo le fa'amamāina ma le fa'ama'i po'o le fa'amama i le fa'ama'i o le hydrogen peroxide.

E iloa e le pa'u pe oi ai se paipa i le agavale i le tamatamailima o le robot e le'i tu'uina i totonu o le ipu paipa, ma fa'agaoioia le masini fa'apipi'i e aveese ai le fa'agaau mai le tamatamailima, ona fa'asolo loa lea e ave le fa'agaau.

LFC4002 Tubes Filling Machine ei ai tulaga lelei nei:

a.Pulea faiga: O le paipa o le faatumu faaaogaina Siemens mata pa'i ma Iapani Keyence motion controller, atoa servo ave pasi;o le pisapisao e itiiti ifo i le 75 decibels.

e.Faiga fa'asinomaga: fa'apipi'i fa'atumu e fa'aaogaina le servo system e pei o le fa'asino igoa, ma fa'atupuina polokalame fa'apitoa e fa'ateleina ai le malosi i le fua fa'atatau, fa'aumi le taimi fa'atumu o le fa'atumu ma fa'amaufa'ailoga, ma fa'amautinoa o le saoasaoa mautu o meafaigaluega e sili atu i le 260pcs / min.

i.Ipu ta'iala ta'iala: O le masini fa'atumu otometi e fa'aogaina le fa'agaoioiga e fa-nofoaga, u'amea u'amea tu'ufa'atasi ta'iala ta'iala, ma le anti-vibration tolu-bearing tube cup holder locking mechanism.

o.Vaevaega o vaega: faʻamama faʻamaʻi, faʻapipiʻi masini robot, faʻapipiʻiina o le servo flap tube, faʻapipiʻi faʻapipiʻi otometi, faʻatumu ma faʻamaufaʻailogaina, faʻaogaina o le servo tube ma isi vaega e vavae ese e tusa ai ma manaʻoga GMP.

u.Tulaga pusa paipa: O le masini faʻatumu faʻapipiʻi faʻapipiʻi e faʻaaogaina le felauaiga faʻalua.O le pusa fagogo o loʻo feaveaʻi i luga o le pito i luga, faʻatulagaina i luga o le faʻailoga faʻafefe, ma le pusa avanoa e toe faʻafoʻi i luga o le pito i lalo.

f.Tube uta auala: Robot poʻo masini faʻapipiʻi faʻapipiʻi e ulu atu i paipa, ma mafai ona teuina 3000-4000 paipa.

h.Servo benchmarking: ma'i lanu lanu faailoga pu'eina, tele torque servo rotation tulaga, maualuga saoasaoa ma mautu.

i.Servo faʻatumu: O le masini faʻatumu faʻapipiʻi otometi e faʻaogaina le laina servo drive atoa ma le pamu sima atoa, e le mafai ona pala.

j.Fa'amauina o paipa alumini ma fa'apalapala: O le fa'apipi'iina ma le fa'apalapala o le masini fa'amaufa'ailoga si'usi'u na mua'i fa'apipi'iina seleulu-ituaiga, e faigofie ona oomi le ea i totonu o le paipa.O lea la ua suia i se masini e pipii faalava ma faamafolafola, lea e leai se pefu ma aloese mai le aveina o le kesi i totonu o le paipa.

k.Fa'amaufa'ailoga o le si'usi'u alumini: A fa'amauina le si'usi'u, o le gaugau ma le pipii e fa'aogaina le fa'alava fa'ata'amilosaga fa'ata'ita'iga (muamua o le arc pick-up type) e aunoa ma le tosoina o le fa'agaau i luga.O lenei mea e sili ona talafeagai mo siʻusiʻu faʻatolu.

n.Fa'amalo masini: O le servo e tu'u ese le fa'auala ma e iai se galuega e tete'e ai.

o.Fa'asoa fa'atasi: servo fe'avea'i fe'avea'i, va'aiga tu'uese'ese fa'asalalau, lelei fa'atasi.

i.Pressure hopper: faʻaogaina le auala vave tatala o le paipa tufatufa e faʻafesoʻotaʻi i le pamu faʻatumu.

q.CIP i luga ole laiga: E mafai ona fufulu ile luga ole laiga pe tuusao.

Parakalafa fa'apitoa

- Tubes Filling Machine Mea fa'apitoa fa'apitoa

| No | fa'ata'oto | saunoaga | |

| Fa'amatalaga o paipa(mm) | Diamita 13 ~ 30, umi 60 ~ 250 |

| |

| Fa'ailoga lanu (mm) | ±1.0 |

| |

| Fa'atumu gafatia(ml) | 1.5~200(Faʻafeiloaʻi 5g-50g faʻamatalaga, faʻamatalaga faʻapitoa ma lapopoa e tusa ai ma ituaiga ma tekinolosi) |

| |

| Faatumu sa'o(%) | ≤±0.5 |

| |

| Fa'amaufa'ailoga si'usi'u | O lo'o avanoa fo'i gauga fa'alua, fa'atolu, ma foe. |

| |

| Fa'aulufalega gafatia PPm | 250-300 |

| |

| Faagaau talafeagai | paipa alumini paipa palasitika paipa palasitika alumini |

| |

| Malosiaga fa'aaogā (kW) | paipa faatumu | 35 |

|

| Robot | 10 |

| |

| Malosiaga | 380V 50Hz |

| |

| mamafa o le ea | 0.6MPa |

| |

| Fa'aaogāina o le ea (m3/h) | 20–30 |

| |

| Fa'ailoga filifili fa'asalalau | (Aulafo mai Italia) Rebar fa'amuta fa'atasi (servo drive) |

| |

| auala fa'asalalau | Ta'avale servo atoa |

| |

| tele(mm) | Umi 3700 Lautele 2000 Maualuluga 2500 |

| |

| mamafa atoa(kg) | 3500 | ||

Smart zhitong e tele tagata faʻapolofesa faʻapolofesa, e mafai ona mamanuinaMasini Faatumu Tubese tusa ai ma manaoga moni o tagata faʻatau

Fa'amolemole fa'afeso'ota'i mai mo se fesoasoani e leai se totogi @whatspp +8615800211936

Vaega o oloa

-

I-meli

-

Telefoni

-

Luga

0086 15800211936

0086 15800211936